New technique of corrosion resistant nickel alloy coatings can replace toxic chrome plating (GS Paper 3, Science and Tech)

Why in news?

- Scientists at the Centre for Engineered Coatings at International Advanced Research Centre for Powder Metallurgy & New Materials (ARCI), has developed a lab-scale process to deposit novel nanostructured Nickel alloy coatings.

Background:

- With ever-increasing demand for high-performance materials in engineering applications, nano-crystalline coatings can cater to the need for the replacement of environmental hazardous chrome coatings.

- Chrome coatings have been used in plastic bottling industry to improve the service life of die-casting components.

- However, chrome plating is a toxic process, and the stringent standard permissible exposure limit (PEL) for toxic hexavalent chromium and all its compounds has to be complied in all chrome plating industrial workplaces.

- Finding a procedure for adhering to this limit is a challenge for scientists.

New research:

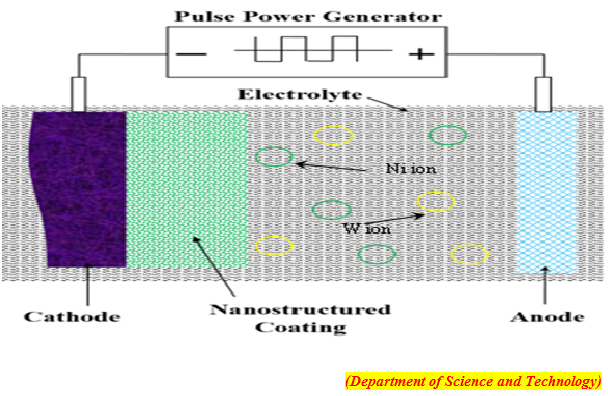

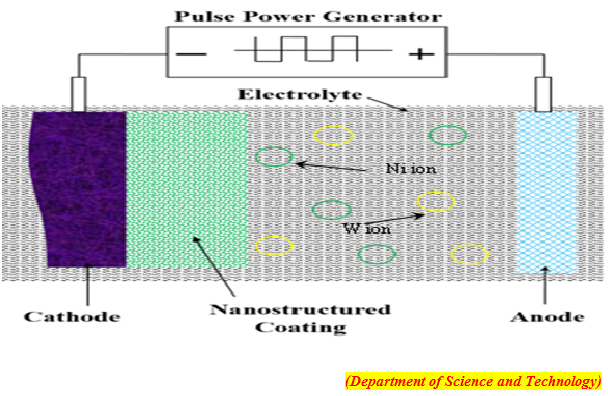

- The process uses pulsed current electroplating, which is environmentally benign with high production capacity. In contrast to conventional, direct current used for chrome plating, the research group have used electric current in the form of pulses of duration of a few milliseconds for electroplating purpose.

- The process consists of environment-friendly electrolyte consisting of nickel and tungsten ions that is the source of strengthening elemental tungsten (W) and nickel (Ni).

Pulsed current effect:

- The pulsed current is applied between the components to be coated, acting as cathode and non-consumable anode.

- The pulsed current effect was used for nano-crystalline coatings wherein high instantaneous current density for very small duration resulted in high rate of nucleation.

- Unlike in conventional direct current plating, the coatings were virtually porosity free, crack free with minimal hydrogen uptake.

- The use of pulsed current resulted in the nano-crystallization of nickel tungsten alloy coatings with high hardness (700-1200 HV) and wear resistance. The coatings were extremely corrosion resistance and could withstand up to 700 hrs of salt spray.

Outcome:

- The coatings developed at ARCI can withstand temperatures up to 500°C without thermal softening and can improve the life of die components by at least two times than conventional chrome plating.

- They were successfully applied to die-casting components used in plastic bottling industry, wherein the temperatures at the die interface can be over 280°C.

Way Forward:

- With numerous applications in automotive, defense, and aerospace for these coatings, the process know-how is ready for transfer as a replacement for conventional chrome plating.

Centre to set up micro-seismic observation systems at Joshimath: Minister

(GS Paper 3, Environment)

Why in news?

- Recently, the Centre announced that it will install micro seismic observation systems at Joshimath, the gradually sinking Himalayan town in Uttarakhand.Earth Sciences Minister made the announcement at the India-UK Workshop of Geosciences.

Why it matters?

- There was a critical need for fundamental research on the physical processes that lead to failure of the brittle layers beneath the crust and sub-crust.

- The human consequences of natural disasters in India were rising rapidly and stressed on the need to devise proper mitigation strategies.

Case of Joshimath:

- The seismic microzonation study for the area would generate risk resilient parameters for safer dwellings and infrastructure.

- They said Joshimath falls under the highest seismic hazard Zone V as it experiences continuous seismogenic stresses.

- Seismic energy generation due to micro-earthquakes may have weakened the strength of the rocks as Joshimath is located in the earthquake rupture zone of the 1999 Chamoli earthquake.

- Climatic factors such as excessive precipitation and flow of water from mountains into massive cracks and fractures in the sub-surface rocks lead to widening of cracks and hastening the slip in rock material.

Way Forward:

- The scientific understanding of the processes behind disasters has grown immensely over the past 50 years, and there is a need for strengthening further international collaborations like the Indo-UK initiative to fight such disasters.

- The Ministry of Earth Sciences had established 37 new seismological centres in the last two years for extensive observation facilities, generating a huge database for outcome-oriented analytics.

- In the next five years, 100 more such seismological centres will be opened across the country for improving real time data monitoring and data collection.

Greenko Group to set up Pumped Storage Project in MP's Neemuch

(GS Paper 3, Environment)

Why in news?

- The Greenko Group, one of India's leading energy transition companies, will invest Rs 10,000 crores in a Pumped Storage Project (PSP) near Gandhi Sagar in Madhya Pradesh's Neemuch district.

Key Highlights:

- The Greenko Group will set up the PSP with a daily storage capacity of 11 GWh (Gigawatt hours).

- The infirm renewable electricity stored in the PSP project during lean demand hours shall be later despatched to help meet the state's evolving peak power demand, thus resulting in considerable cost savings.

- Besides, the PSP project shall enable MP state to meet its statutory RPO (Renewable Power Obligation) and the recently notified ESO (Energy Storage Obligation) targets.

- This project is expected to provide employment to over 4,000 people.

Way Forward:

- Greenko currently operates wind and solar of over 500 MW capacities, across five districts of Madhya Pradesh.

- Greenko's PSP is expected to be commissioned by December 2024 and will be connected to the ISTS (Inter-State Transmission System) network.