Rat hole mining (GS Paper 3, Environment)

Why in news?

- Efforts to release 41 workers trapped in the collapsed Silkyara-Barkot tunnel in Uttarakhand seemed close to a breakthrough, after rat-hole miners were reported as being only a few metres away from them.

- Rat-hole miners were called in after the auger machine that was drilling through the debris broke.

What is rat-hole mining?

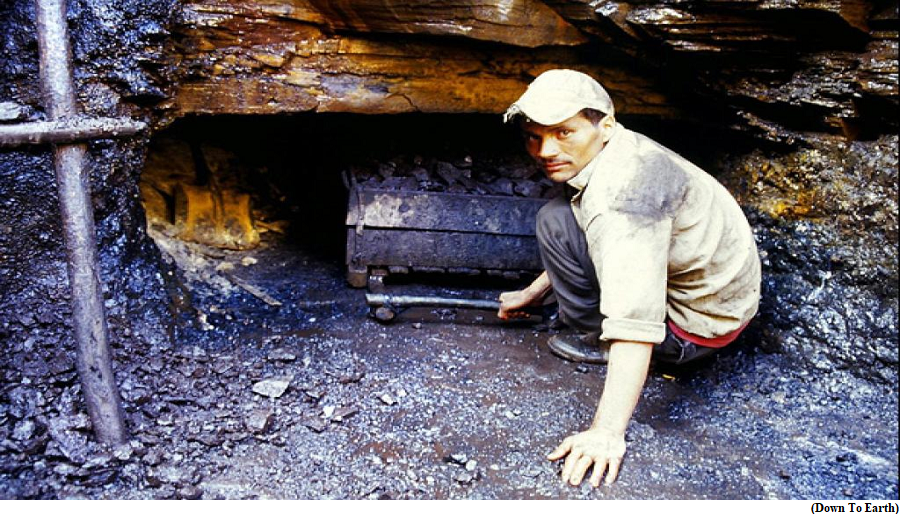

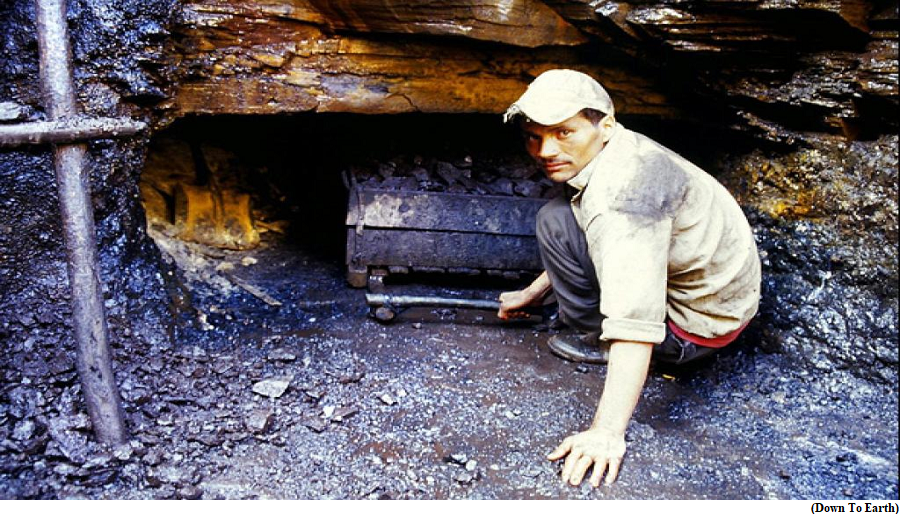

- Rat hole mining is a method of extracting coal from narrow, horizontal seams, prevalent in Meghalaya. The term “rat hole” refers to the narrow pits dug into the ground, typically just large enough for one person to descend and extract coal.

- Once the pits are dug, miners descend using ropes or bamboo ladders to reach the coal seams. The coal is then manually extracted using primitive tools such as pickaxes, shovels, and baskets.

The rat-hole mining is broadly of two types:

- In the side-cutting procedure, narrow tunnels are dug on the hill slopes and workers go inside until they find the coal seam. The coal seam in hills of Meghalaya is very thin, less than 2 m in most cases.

- In the other type of rat-hole mining, called box-cutting, a rectangular opening is made, varying from 10 to 100 sqm, and through that a vertical pit is dug, 100 to 400 feet deep. Once the coal seam is found, rat-hole-sized tunnels are dug horizontally through which workers can extract the coal.

Environmental & safety concerns:

- Rat hole mining poses significant safety and environmental hazards. The mines are typically unregulated, lacking safety measures such as proper ventilation, structural support, or safety gear for the workers. Additionally, the mining process can cause land degradation, deforestation, and water pollution.

- This method of mining has faced severe criticism due to its hazardous working conditions, environmental damage, and numerous accidents leading to injuries and fatalities.

- Despite attempts by authorities to regulate or ban such practices, they often persist due to economic factors and the absence of viable alternative livelihoods for the local population.

When was it banned, and why?

- The National Green Tribunal (NGT) banned the practice in 2014, and retained the ban in 2015.

- The order was in connection with Meghalaya, where this remained a prevalent procedure for coal mining. The state government then appealed the order in the Supreme Court.

Fibre optic cables, its origins, working and different functions

(GS Paper 3, Science and Technology)

Context:

- During the unprecedented COVID-19 pandemic, the one thing that connected people virtually was the internet. It brings into picture role of optical fibre and its working.

What is an optical fibre?

- Optical fibres are made of thin cylindrical strands of glass. The diameter of a typical fibre is close to the diameter of a human hair.

- These fibres can carry information, such as text, images, videos, telephone calls, and anything that can be encoded as digital information, across large distances almost at the speed of light.

- Ultra-thin fibres seem very fragile. But when manufactured correctly as a long thread surrounded by protectives, they serve the purpose in a durable way.

- They are strong, light, and flexible, and ideal to be buried underground, drawn underwater, or bent around a spool.

How do optical fibres work?

- Light is an electromagnetic wave with a spectrum of frequencies.

- When a beam of light falls on a glass surface, it passes through partially while the rest is reflected away. When it passes through, its path bends because the refractive index of glass is different from that of air. The refractive index is the property of a medium that determines how fast light can travel in it.

- When a beam travels in the reverse direction, that is from glass to air, it’s possible that it won’t enter the air. Instead, it will be completely reflected back within the glass. This phenomenon, known as total internal reflection, is the basis of guiding light across long distances without a significant loss of optical power.

- With proper adjustments, the light can be kept bouncing within the glass with very little escaping outside. This is how signals encoded as electromagnetic waves can be fed into one end of an optical fibre, and they will reflect and bounce many times between the glass walls as they traverse several kilometres bearing the information in the signals.

Components:

A fibre optic communication system consists of three parts —

- a transmitter which encodes information into optical signals (in the form of rapidly blinking light pulses of zeros and ones);

- an optical fibre that carries the signal to its destination; and

- a receiver which reproduces the information from the encoded signal.

- Optical waves allow a high data-transmission rate, up to several terabits per second in a single fibre. Unlike radio or copper-cable-based communication, fibre cables are also insensitive to external perturbations such as lightning and bad weather.

How were fibre optic cables developed?

- While the intriguing effects of light in transparent media like water or glass was known, the systematic development of light-guiding can be traced only to the early 19th century.

- In 1840, Jean-Daniel Colladon at the University of Geneva first demonstrated that light’s propagation can be restricted to a narrow stream of a water jet.

- John Tyndall is known for popularising the idea of Colladon’s light fountains. Following a suggestion by Michael Faraday, he demonstrated the effect in a water jet at the Royal Society in London in 1854. The effect is also visible in plastic-fibre Christmas trees.

- In the 1920s, Clarence Hansell and John Logie Baird showed a way to transmit images through glass fibres.

- Around the 1930s, doctors started using a bundle of thin fibres to inspect patients’ internal organs and to illuminate teeth during surgical procedures.

Post 1950s:

- In 1954, fibre development made a significant leap forward. Harold Hopkins and Narinder Singh Kapany at Imperial College London transmitted images using a 75-cm-long bundle of more than 10,000 optical fibres.

- Two years later, Lawrence E. Curtiss at the University of Michigan developed the first glass-clad fibres. In the same year, Kapany coined the term ‘fibre optics’.

- In 1960, Theodore Maiman built the first laser which further boosted research in optical communication. The development of lasers working at room temperature made it possible to code any information digitally into optical signals. However, sending such light signals across long distances was still a big challenge.

- In 1966, Charles Kao and his colleagues found that the signals were attenuated due to impurities in the glass rather than the light being scattered. He suggested melting high-purity fused silica at high temperatures and producing thin fibre threads from that.

- This way, the decay of light signals inside glass fibres could be reduced below 20 decibels per kilometre (dB/km) meaning 1% of the signal could still be detected after a kilometre.

- In 1971, the American glass-making company Corning Glass Works achieved this value in a finished cable.

Current technology:

- Nowadays, glass fibres are manufactured using the fibre-drawing technique. First, a thick glass rod, called preform, of high purity and an engineered refractive index profile is prepared using chemical vapour decomposition.

- The preform is heated to about 1,600 degrees Celsius until it melts and is then drawn into a thin, long fibre. The drawing process reduces the fibre’s diameter while maintaining its length. The drawn fibre is coated with a protective layer to enhance strength and durability.

- In India, the Fibre Optics Laboratory at the Central Glass and Ceramic Research Institute, Kolkata, has a facility to manufacture high-quality silica-based optical fibres. Today’s optical fibres have a typical loss of less than 0.2 dB/km.

What is the future of fibre cables?

- Fibre optics technology has since been used in telecommunication, medical science, laser technology, and sensing.

- With a goal to securing communication and promoting quantum science, the Government of India announced a national mission in the Union Budget of 2020.

- The proposed budget for this ‘National Mission on Quantum Technologies and Applications’ is ₹8,000 crore over a period of five years.

As deaths due to work-related factors go up, ILO report urges countries to strengthen safety net

(GS Paper 3, Economy)

Why in news?

- Recently, the International Labour Organization (ILO) released a report titled, “A Call for safer and healthier working environments”.

- It will be discussed at the 23rd World Congress on Safety and Health at Work, in Sydney.

- The report said mining and quarrying, construction, and utilities sectors were the three most hazardous sectors globally.

Key Highlights:

- It says nearly 30 lakh workers die every year globally owing to work-related accidents and diseases. More than 63% of these deaths are reported from the Asia-Pacific region.

- Exposure to long working hours (55 hours or more per week) was the biggest “killer”, with almost 7.45 lakh people dying of it in 2016, followed by exposure to occupational particulate matter, gases, and fumes (4.5 lakh deaths) and occupational injuries (3.63 lakh deaths).

- A majority of these work-related deaths, 26 lakh, was attributed to work-related diseases, while work accidents resulted in 3.3 lakh deaths. The diseases that caused most work-related deaths were circulatory diseases, malignant neoplasms and respiratory diseases.

- The report said that the rate of trachea, bronchus, and lung cancers attributable to occupational exposure to chromium doubled between 2000 and 2016.

- Mesothelioma, attributable to asbestos exposure, has risen by 40%. The rate of non-melanoma skin cancer increased by over 37% between 2000 and 2020.

- On the other hand, deaths due to exposure to asthmagens and particulate matter, gases, and fumes decreased by over 20%.

ILO conventions:

- So far 79 out of the 187 member countries have ratified the ILO Occupational Safety and Health Convention (No. 155), while 62 countries have ratified the Promotional Framework for Occupational Safety and Health Convention, 2006 (No. 187). India has not ratified both the conventions.

- In the wake of the Uttarkashi tunnel collapse in which 41 workers have been trapped, the Central trade unions had urged the Union government to ratify the conventions.

- In line with the core principles of the two fundamental Conventions, a sound and resilient national occupational safety and health framework, built on social dialogue and participation, is essential for the realisation of the fundamental right to a safe and healthy working environment.

Recommendations:

- The report recommended five categories of “Fundamental Principles and Rights at Work” for ensuring safety and health at work.

- These are freedom of association and the effective recognition of the right to collective bargaining, elimination of all forms of forced or compulsory labour, abolition of child labour, elimination of discrimination in respect of employment and occupation, and a safe and healthy working environment.