Easing the transport of cargo by Railways (GS Paper 3, Infrastructure)

Context:

- The Railways has been one of the more cheaper modes of transportation for moving bulk cargo.

- The government has therefore realised that it needs to be supported with reduced overall logistics costs and schemes to improve green mobility.

Specific Policy:

- Identifying infrastructure investment in the sector as a key thrust area, the Government of India has formulated two policies

- the PM GatiShakti (PMGS) policy for a National Master Plan (NMP) and

- the National Logistics Policy (NLP).

- The PMGS aims to bring synergy to create a seamless multi-modal transport network in India, with the NMP employing technology and IT tools for coordinated planning of infrastructure.

- The NLP focuses on building a national logistics portal and integrating platforms of various ministries.

Other initiatives:

- In reference to the Indian Railways (IR), the Department for Promotion of Industry and Internal Trade’s website mentions three things:

- integration of postal and railway networks,

- one station – one product and

- the introduction of 400 Vande Bharat trains without anything about increasing the IR share in moving cargo.

Focusing on bulk cargo:

- The IR has taken some initiatives in the bulk cargo arena. It relaxed block rake movement rules to provide a facility to load from/to multiple locations, permitted mini rakes, introduced private freight terminals (PFTs) and relaxed conditions in private sidings.

- The Gati Shakti Terminal (GCT) policy has eased the stipulations for the operation of these terminals and progressively all PFTs and private sidings are being converted into GCTs.

- The IR has also partnered with freight operators in recent years, encouraging them to invest in wagons for movement of their cargo thus helping in the induction of more than 16,000 privately-owned wagons to facilitate specialised traffic like automobiles and fly ash.

Challenges:

- While it is early to judge the impact of these initiatives, the IR’s share in bulk cargo continues to decline. Some decline is expected as production becomes more decentralised and the IR’s cost advantage diminishes. To offset this, IR should reduce non-price barriers and distribute transaction costs associated with it to as many customers as possible.

- A railway siding is a capital-intensive high-cost proposition and only large industries can manage them with others having to cover large distances to load their cargo. This increases the logistics costs and hence the reluctance to patronise the IR.

- For example, in the cement sector in 2017-18, thirty-three plants with less than one million tonne (MT) annual capacity had a production share of 6.5% but their share in rail loading was 3.8% whereas plants with more than 2.5 MT annual capacity with a production share of 57%, the rail share was 69.5%. Similar is the picture for many private mines, mini steel plants, agricultural markets etc.

Role of state governments:

- There is an immediate need to develop common-user facilities at cargo aggregation and dispersal points in mining clusters, industrial clusters and large cities. The knowledge of these clusters rests with the States and not the IR or other central ministries, and thus collaboration with State governments is a sine qua non. The relationship of the IR with State governments has been a sort of patron-client relationship as many States regularly demand rail lines in their areas.

- A change in this attitude is necessary in order for the Railways to participate in the planning of industrial clusters and mines in cities/regions if it has to increase its share in the movement of cargo.

Environmental constraints:

- The Ministry of Environment and Forests (MoEF) started issuing notifications since 1999 for the complete utilisation of fly ash; in 2021 the production was 232 MT and utilisation was 214 MT.

- The IR never realised the potential and approved many power plant sidings without fly ash loading facilities rendering it to be a minor player in its transportation, and it must proactively correct this wrong.

Efficient loading:

- Another necessity is for the IR to encourage and liberalise the design of new wagons amenable to higher and efficient loading to deal with new commodities.

- Finally, environmental considerations are constraining loading by the IR. As per recent government regulations, environmental clearance for rail loading/unloading facilities has been made mandatory but the same has not been imposed on road loading/unloading facilities.

- These restrictions have made some users move cargo by road due to high transaction costs involved with environmental clearances.

- Such instructions should be mode-agnostic, based on the quantity of cargo loaded and the potential for environmental degradation. Otherwise rail loading will be hampered giving fillip to more environmentally polluting road transport.

The expansion of settlements into flood prone areas

(GS Paper 3, Environment)

Why in news?

- India’s urban areas have been flooding more and more often, destroying lives and livelihoods. Yet, according to a study led by the World Bank flood risk in many cities is rising because they are expanding into flood-prone areas.

Details:

- According to the paper, since 1985, human settlements in flood-prone areas have more than doubled. Experts say the findings spotlight the risk of unsustainable urbanisation in India.

- The study also found that middle-income countries like India have more urban settlements in flood-prone zones than low- and high-income countries.

How is India at risk?

- India isn’t among the 20 countries whose settlements are most exposed to flood hazards, but it was the third highest contributor to global settlements, after China and the U.S., and also third after China and Vietnam among countries with new settlements expanding into flood-prone areas, all from 1985 to 2015.

- This means India is at significant risk of flood-related problems that could worsen in the coming years if the country wasn’t careful.

Who are most affected?

- The risks are disproportionately higher for those living in informal structures.

- The geography of environmental risk is also the geography of informal low-income housing. Informal housing in cities is on “land that is vacant and less desirable, so that they are not immediately driven off. So they often lie in “low-lying, flood-prone areas”.

- Urbanisation has expanded into flood-prone areas due to lack of governance processes. When environmental regulations are applied to new constructions, they are often applied only to big infrastructure projects and not to medium- and small-scale modifications of localities.

- This contradicts the notion that certain localities are more flood-prone and that flooding and flood-risk are locality-level issues.

- The people commonly violate existing government regulations. Examples include rise in eco-tourism resorts on forest land and the construction of large structures, including government buildings and even religious structures, on rivers’ floodplains.

What is to be done?

- Some forms of adaptation are necessary and they need to differentiate between low-income residents and unauthorised structures erected for the elite.

- Every city needs to do a proper scientific mapping of the flood prone areas. The urban governments need to make housing in such areas more flood-resilient and protect low-income housing.

The act of photocopying, its origins, working and wide ranging impact

(GS Paper 3, Science and Technology)

Context:

- Xerographic machines are in ubiquitous use around the world today to quickly and cheaply reproduce printed material.

What is photocopying?

- Broadly, photocopying is a set of techniques used to duplicate content using, among other things, light. However, the contemporary colloquial use of the word ‘photocopying’ refers almost exclusively to xerography.

- Both the word ‘xerography’ and the name ‘Xerox’ come from the Greek root-word ‘xero’, meaning ‘dry’. This is because xerography is a type of photocopying method where the process doesn’t involve messy liquid chemicals.

How does xerography work?

Photoconductive surface:

- The first is the photoconductive surface, a surface coated with a photoconductive material. Such a material, when exposed to light, allows electrons to flow through it (that is it conducts electricity) but blocks them when it’s dark. This surface is negatively charged by placing a thin negatively charged wire with a high voltage next to it.

- Then, the sheet of paper to be copied is illuminated with a bright light. The darker parts of the paper don’t reflect the light whereas the unmarked parts do.

- This reflected light is carried by lenses and mirrors to fall on the photoconductive surface. In the parts of the surface where light falls, the photoconducting material will become conductive and allow the electrons near its surface to dissipate downwards (into a grounding).

- So the parts that remain negatively charged at the end of this step will correspond to parts of the paper-to-be-copied (TBC) where something was printed.

Toner:

- Next, a powdery substance called toner is applied to the surface. The toner is positively charged, so it will settle where negative charge persists on the surface.

- The surface then transfers the pattern of the toner on it to a sheet of paper. The paper has a stronger negative charge that causes the toner to jump.

- Finally, the toner is heated so that it melts and fuses with the paper. This is the paper that rolls out of the photocopying machine, the whole process having been completed in a few seconds. In practice, a rotating drum is used instead of a flat surface, and the paper TBC is illuminated by a flashing or stroboscopic light or a moving scanner.

Who invented xerography?

- Inspired by the work of the Hungarian engineer Paul Selenyi, an American attorney named Chester F. Carlson came up with a rudimentary version of xerography by 1938.

- Seven years later, he sold his idea to a non-profit organisation called the Battelle Memorial Institute in Ohio, where researchers refined the technique.

- In 1946, the small New York-based Haloid Photographic Company purchased a licence from Battelle to build a machine based on the technique. The company trademarked the name for this machine as the “Xerox machine” in 1948 and availed the first model for sale in 1949. Haloid’s managers were responsible for coining the word ‘xerography’, replacing Carlson’s ‘electrophotography’.

- About a decade later, Xerox also introduced the laser-based photocopier. Instead of using a lamp to reflect light off the document to be copied to the drum, the data to be copied was encoded as a bitmap that was fed to a laser, which then inscribed the requisite shapes onto the drum.

Xerography’s wide-ranging impact:

Counterfeiting:

- In 2002, people discovered that Xerox machines refused to copy banknotes that included a particular marking, of five small rings positioned like stars in the Orion constellation. Similar markings have since been found on the banknotes of at least 35 national banks.

- A 2005 statement from the Reserve Bank of India, accompanying the release of new ₹50 notes, called it the “Omron anti-photocopying feature”, suggesting that a Japanese corporation named Omron was responsible for designing the rings to prevent counterfeiters from duplicating or printing currency notes using xerographic machines.

Copyright & surveillance:

- In 2012, a raft of academic publishers, including the Oxford University Press, filed a suit alleging copyright infringement against a photocopy shop and the University of Delhi.

- The suit claimed that teachers at the university had picked pages from books by the publishers to be copied and bound together at the shop, and sold to university students at ₹0.50 per page.

- The matter famously concluded in the university’s favour, highlighting the rights that attend to and the benefits that accrue from being able to make numerous copies of educational material at a low cost.

IIT team finds carbon flowers excelling at turning light to heat

(GS Paper 3, Science and Technology)

Why in news?

- Scientists at the Indian Institute of Technology, Bombay, (IIT Bombay) have developed a new material that can convert sunlight into heat energy with unprecedented efficiency.

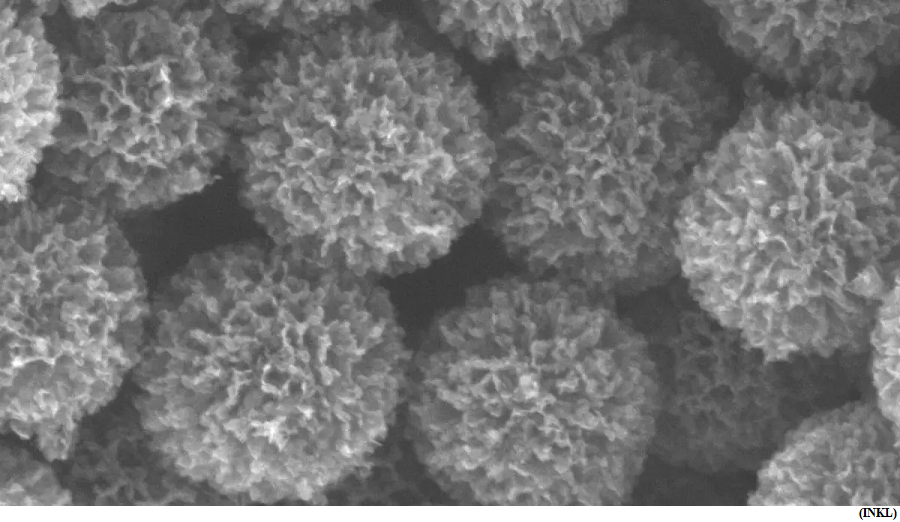

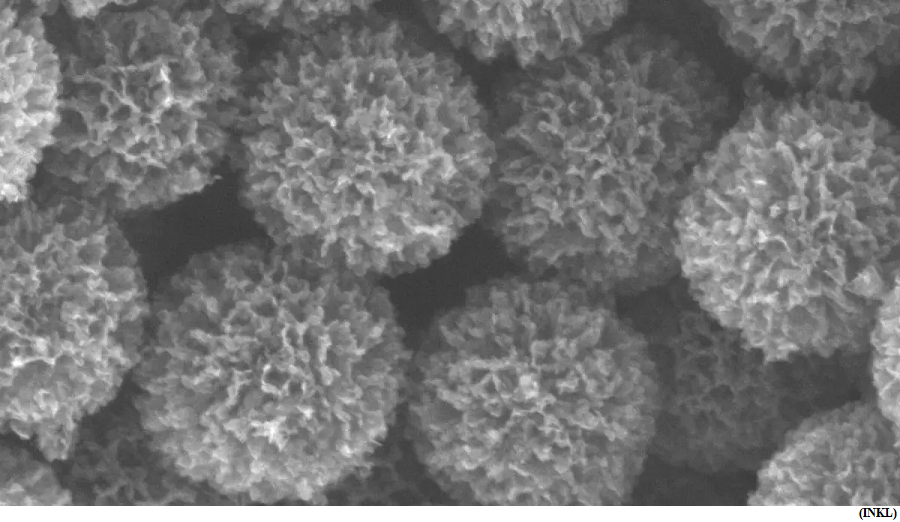

- Due to their appearance like tiny marigold flowers, made only of carbon. They called the material carbon nanoflorets.

- The nanoflorets also didn’t easily dissipate the heat generated into the environment, making the material a good candidate to heat other materials, like water, using solar energy.

How it was made?

- They heated a special form of silicon dust called DFNS (for dendritic fibrous nanosilica) in a furnace. Once heated, they introduced acetylene gas into the chamber. The white powder turned black – a sign that carbon had been deposited on the DFNS.

- Then she collected the black powder and treated it with a strong chemical that dissolved the DFNS away, leaving carbon particles behind.

- The structure of the silicon particles – 50-1,200 nanometers in size – resembled spikes arranged around a sphere.

- With the silicon filling taken away, what was left behind were little carbon beads whose surfaces were pocked with cone-shaped pits. In effect, the beads were spherical nanostructures composed of carbon cones.

Two different techniques:

- In 2018, his own group had reported identical structures that it dubbed “carbon nanospheres with wrinkled cages”.

- But, the work differed in the techniques used to deposit carbon on the DFNS template.

- Earlier team used formaldehyde-phenol polymerisation chemistry whereas now they used chemical vapour deposition (CVD). In CVD, volatile compounds like acetylene are used to deposit a thin carbon film on the silicon-dust template.

Efficiency:

- The team conducted experiments to demonstrate that the nanoflorets converted the light energy they absorbed into thermal energy a process called solar-thermal conversion with a remarkable efficiency of 87%.

The carbon nanoflorets’ high efficiency comes from three properties.

- The nanoflorets absorb three frequencies in sunlight – infrared, visible light, and ultraviolet. Other common materials for solar-thermal conversion, like photovoltaic materials used in solar panels, absorb only visible and ultraviolet light.

- More than half of the energy in sunlight arrives to the earth as infrared radiation. So the nanoflorets can absorb much more energy from the sun.

- The other two properties responsible for the material’s high light-heat conversion efficiency are a result of its shape.

- As light falls on the material, the carbon cones ensure that very little is reflected back. Instead, most light is reflected internally.

- One risk with a material that can convert sunlight into heat is that it can also lose it to its environment.

- The carbon nanoflorets don’t, however, due to long-range disorder: parts of the structure at some distance from each other possess different physical properties.

- As a result, heat waves in the material aren’t carried over long distances, reducing the amount of heat dissipated away.

Way Forward:

- India is a country that is blessed with a lot of light, but also has areas that have low temperatures. In such regions, the nanofloret coatings can help heat up housing and sterilise surfaces in hospitals.

- The researchers are also studying the nanoflorets’ other physical and chemical properties and potential applications.